VB Engineering

VB Engineering is pioneer in providing Arc Flash Risk assessment Services.Our Arc Flash hazard analysis and mitigation services and turn key in nature and completely takes care of your NFAP 70E arc flash hazard analysis requirements.

VB Engineering is expert electrical engineering consultants providing its arc flash hazard analysis services globally.

VB Engineering is pioneer in providing Arc Flash Risk assessment Services.Our Arc Flash hazard analysis and mitigation services and turn key in nature and completely takes care of your NFAP 70E arc flash hazard analysis requirements.

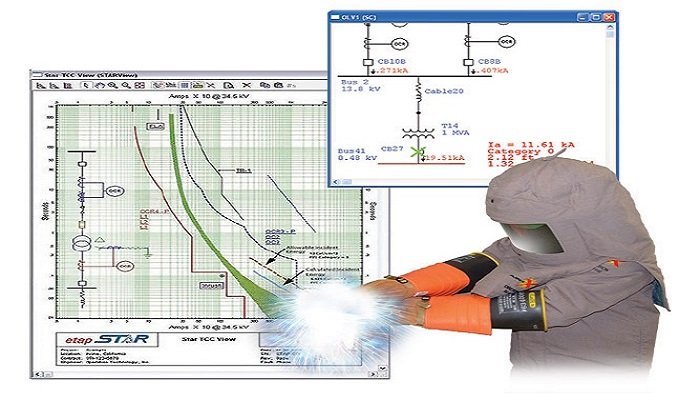

Arc flash testing is the process of determining the arc rating for materials and equipment to be used in electrical hazardous environments. Arc ratings are important in assisting companies and manufactures in staying compliant with OSHA regulations and in keeping their workforce safe in a potential arc flash situation. Arc flash testing allows safer choices of PPE for your hazard and minimizing injury.

What is arc flash ?Arc Flash is the night mare for most of the safety and electrical maintenance engineers in their facility. Osha insists all the plants to perform Arc Flash Risk assessments and implement the mitigation techniques to stay safe as per NFPA 70-E standards.

The Arc Flash Sample report says about the Electrical Hazard Analysis within all areas of the electrical system.The results of the Electrical Hazard Analysis will determine the work practices, protection boundaries, personal protective equipment, and other procedures required to protect employees from Arc-Flash or contact with energized conductors.

An arc flash is a type of electrical explosion. It’s a serious hazard when working on or near energized electrical equipment. OSHA requires that all employees understand the electrical hazards to which they are exposed. This course introduces the dangers of arc flash and presents common methods for preventing and protecting against those dangers.

What is arc flash ?Arc Flash is the night mare for most of the safety and electrical maintenance engineers in their facility. Osha insists all the plants to perform Arc Flash Risk assessments and implement the mitigation techniques to stay safe as per NFPA 70-E standards.

Example of Slow Motion Arc Flash 100A Disconnect showing the impact of body position in arc flash. In the video, the door comes off in less than 2 cycles showing that Personal Protective Equipment (PPE) isn't the only thing to consider when it comes to arc flash. Body position at the point of contact is also important. The training demo shows the elements of the "One Hand Rule", as a guide to safe body position when exposed to potential electrical hazards. The testing in the video is produced by ArcWear the worldwide arc flash testing leader.

The most common cause of Arc Flash and other electrical accidents is carelessness. No matter how well a person may be trained, distractions, weariness, pressure to restore power, or over- confidence can cause an electrical worker to bypass safety procedures, work unprotected, drop a tool or make contact between energized conductors. Faulty electrical equipment can also produce a hazard while being operated.